Do you want to bring life to your glass bottles? If yes, then there is no other way better than adding artwork to it. Screen printing is one such technique that can be used to print images of different artwork on the surface of glass bottles. This method can also be used to protect the outer portion of the glass from getting damaged. Let us have a look at some tips that can help you in screen printing on glass bottles.

Table of Contents

1. Creating a design

The first step that you need to take is to create a design that you want to print on the desired product. While creating a design, make sure to keep in mind the design of the bottle as well. This will help you in creating an appropriate or suitable design for your bottle. Pick a design that will make you stand out from the crowd.

2. Prepare the screen

Once you have made a design, it is time to prepare the screen. The screen mesh that you will select should be dependent upon the thickness of the glass and the design’s intricacy. After you have made your choice, you need to apply a light coating of emulsion on the screen mesh and let it harden under exposure to bright light.

3. Exposing the emulsion

When you expose the emulsion to a very strong light, the design gets transferred from the acetate sheet to the screen coated with light-reactive emulsion. If your designs include more than one color, then you have to apply each ink color on the different screen mesh. To achieve a colorful and flawless design, the person must use his artistic abilities to design different stencils and line them up in an appropriate manner.

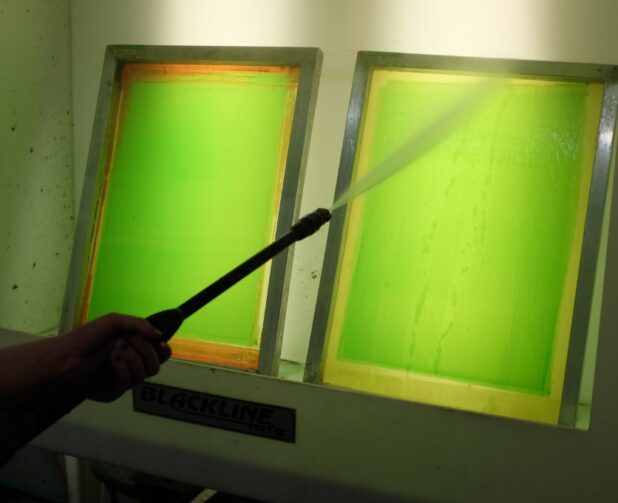

4. Washing off the emulsion

The portion of the emulsion-coated screen that gets a certain amount of lights starts getting hardened. But you need to wash off the emulsion from the portion that isn’t solidified yet. Make sure to do this step very carefully. Once the screen gets completely dry, you can do any alterations to it to ensure that the design resembles the original one. You can now use the stencil as it is complete.

5. Preparing the glass

Once the screen is ready, you have to mount it on the printing press. The glass where you want to create artwork should be kept flat beneath the screen on the printing board. There are two types of presses available: automatic and manual.

However, automatic presses are most used by commercial businesses because of the convenience it provides. Another benefit of using automatic presses is that you can work with multiple screens at the same time. Visit here to find the best automatic printing presses to design beautiful glass bottles.

6. Pressing the ink on the glass

After you have placed the screen on the printing board, it is time to press the ink on the glass. You can use a squeegee to drag the ink on the entire length of the screen. By doing this, you will be able to create a design on the glass that is placed beneath. If you plan to create numerous such pieces, then you can lift the screen and change the glass beneath it. Keep repeating the procedure until you get the desired amount of pieces.

Use a particular solution to clean the emulsion after the work is done. You can also utilize the stencils for another purpose after it has solved this one.

7. Drying the glass

The last step is to let the printed glass dry. After it dries down completely, you will be able to see a smooth and colorful finish. Before passing it to your customers, make sure to examine all the pieces carefully. After all, you do not want to send products that are not designed properly.

Benefits of Screen Printing on Glass Bottles

It helps you stand out

Whenever you decide to be creative with your packaging, it is essential for you to set your goals. Suppose you want to communicate an effective message through it. You can use screen printing to print those messages on the bottles. This is a great idea for attracting more and more customers to your business. It will help you stand out from your competitors in the market.

Such bottles are considered to be of high-quality

There are a lot of packaging options available these days but you have to choose the right one to attract the customers. Most high-end customers look for visually appealing products. Screen-printed glass bottles show the symbol of high quality. When this technique was launched in the market, it was viewed as the top packaging method. The customers are very well aware of the value of the screen-printed glass bottles.

Recyclable and reusable

The best part about such glass bottles is their durability. They can withstand many washes. They can be used for years and years without getting damaged. You can get a caustic sanitizer to ensure that the design remains intact on the outer surface of the bottles. It is also the best way to save the environment from harmful waste. They are not only eco-friendly but also budget-friendly. You are not required to use plastic bottles once you start using such pretty screen-printed glass bottles.

No need for paper labels

You no longer have to use the paper labels on your glass bottles. Another benefit of screen printing is that it has reduced paper wastage. The worst part about the paper labels is that they get wrinkles very easily. They usually slip from the surface of the bottle and your label can no longer be seen on the glass bottle. That is why you should use screen printing techniques to avoid issues created by paper labels.

To Sum Up

One of the best ways of creating art on glass bottles is screen printing. This technique is also budget-friendly and eco-friendly. The method is not that tough to use. All you have to do is keep in mind certain steps. Check out the steps given above to create the best screen-printed glass bottles.

World Magazine 2024

World Magazine 2024